Truck maintenance keeps your fleet safe and reduces repair costs. This guide covers daily checks, maintenance schedules, and common problems. Keep reading to maintain your trucks effortlessly.

Table Of Content

- Understanding Truck Maintenance

- Essential Daily Checks

- Preventive Maintenance Schedule

- Cost of Truck Maintenance

- Common Maintenance Issues and Solutions

- Empowering Drivers for Maintenance

- Tools and Equipment for Effective Maintenance

- Importance of Adhering to Regulations

- Planning for Long-Term Reliability

- Summary

- Frequently Asked Questions

Key Takeaways

- Regular truck maintenance is essential for safety, efficiency, and longevity, helping to avoid costly repairs through a structured preventative maintenance schedule.

- Daily inspections by drivers, focusing on key components like fluids, tires, and brakes, are crucial for identifying potential issues before they escalate into major problems.

- Adhering to federal and state regulations for maintenance ensures compliance, enhances safety, and mitigates legal risks for trucking companies.

Understanding Truck Maintenance

Regular truck maintenance is the backbone of a reliable and efficient fleet. Routine maintenance is essential for ensuring that trucks operate safely and efficiently on the road. A preventative maintenance schedule significantly extends your vehicles’ lifespan, keeping them roadworthy and dependable for years. This not only enhances reliability but also helps avoid unexpected and costly repairs.

Maintaining a thriving trucking business hinges on a well-structured semi truck maintenance plan. Preventive maintenance involves scheduled inspections and tasks aimed at addressing potential issues before they escalate into major problems. A proactive maintenance approach sustains profit margins, keeps your fleet running smoothly, and ensures your business remains competitive and efficient.

Essential Daily Checks

Daily inspections are the frontline defense against potential truck issues. Daily checks prevent minor problems from becoming major issues, keeping your trucks in good condition. Drivers should inspect key components such as engine oil, coolant, tires, lights, and the overall condition of the vehicle daily.

These routine inspections are vital as they help identify potential issues before they escalate into serious problems.

Fluid Levels

Checking fluid levels daily is crucial to prevent unplanned downtime and maintain truck performance. Under the hood, essential fluids like engine oil, coolant, transmission fluid, brake fluid, and power steering fluid should be monitored regularly. A drop in fluid levels can indicate a consumption or leak problem, making it essential to monitor regularly.

To avoid downtime caused by fluid leaks, keep critical fluids topped off and consider carrying spare fluids. Failing to check fluid levels regularly can lead to safety risks, increased repair costs, and unwanted downtime.

Tire Pressure and Condition

Maintaining proper tire pressure is crucial for safety and can prevent premature tire damage. Regular tire pressure checks help avoid uneven wear, maximize fuel economy, and ensure proper traction, braking, and load-carrying capabilities. Additionally, routine tire inspections help avoid dangerous blowouts and increase safety.

Daily tire checks should include looking for unusual wear and damage to tire treads and sidewalls, including assessing tread depth. Alignments can help prevent uneven tire wear and extend tire lifespan, while regularly rotating tires can help manage uneven wear and extend their usable life.

Lights and Brakes

All lights must function correctly for visibility and safety, especially at night. The FMCSA mandates that truck operators perform regular inspections to ensure vehicles meet safety standards. Drivers should check for even brake wear patterns from side to side and front to back to ensure optimal braking performance.

Regular inspections of the truck’s electrical system, including lights and brakes, are essential for maintaining safety and avoiding potential accidents.

Preventive Maintenance Schedule

A preventive maintenance schedule is your roadmap to reducing maintenance costs and ensuring truck reliability. A regular maintenance schedule can significantly lower overall costs. Preventive maintenance involves scheduled inspections and tasks that aim to preemptively address vehicle issues before they lead to breakdowns, and a preventative maintenance checklist can help ensure that all necessary tasks are completed.

Following manufacturer’s recommendations in maintenance ensures proper maintenance and performance. Maintenance intervals vary based on the truck’s age and mileage, with newer trucks requiring less frequent maintenance compared to older models.

Engine and Transmission

Engine oil changes are crucial for maintaining engine health, with intervals ranging from every 10,000 to 25,000 miles depending on the manufacturer’s guidelines. Identifying and fixing leaks in the transmission through regular maintenance prevents significant damage.

Following the manufacturer’s suggestions when changing truck fluids prevents higher repair costs and breakdowns. Additionally, air filters should be inspected and changed at regular intervals, more often if driving on dirty, dusty roads.

Brake System

Regular inspections of the braking system can help prevent accidents caused by brake failures. Truck brakes should be inspected every time you stop to ensure optimal performance. Drum brakes are one of the components that require frequent inspections due to their tendency to wear quickly.

Drivers need to know how to check brakes as part of their pre-trip inspections to ensure safety.

Seasonal Adjustments

Seasonal changes can affect various truck systems, necessitating adjustments to maintenance routines to ensure optimal performance. Seasons affect truck systems like cooling and batteries differently. Adjusting maintenance routines is essential to prepare for the challenges posed by each season.

Proper seasonal adjustments help maintain truck performance and durability, ensuring safety and efficiency year-round.

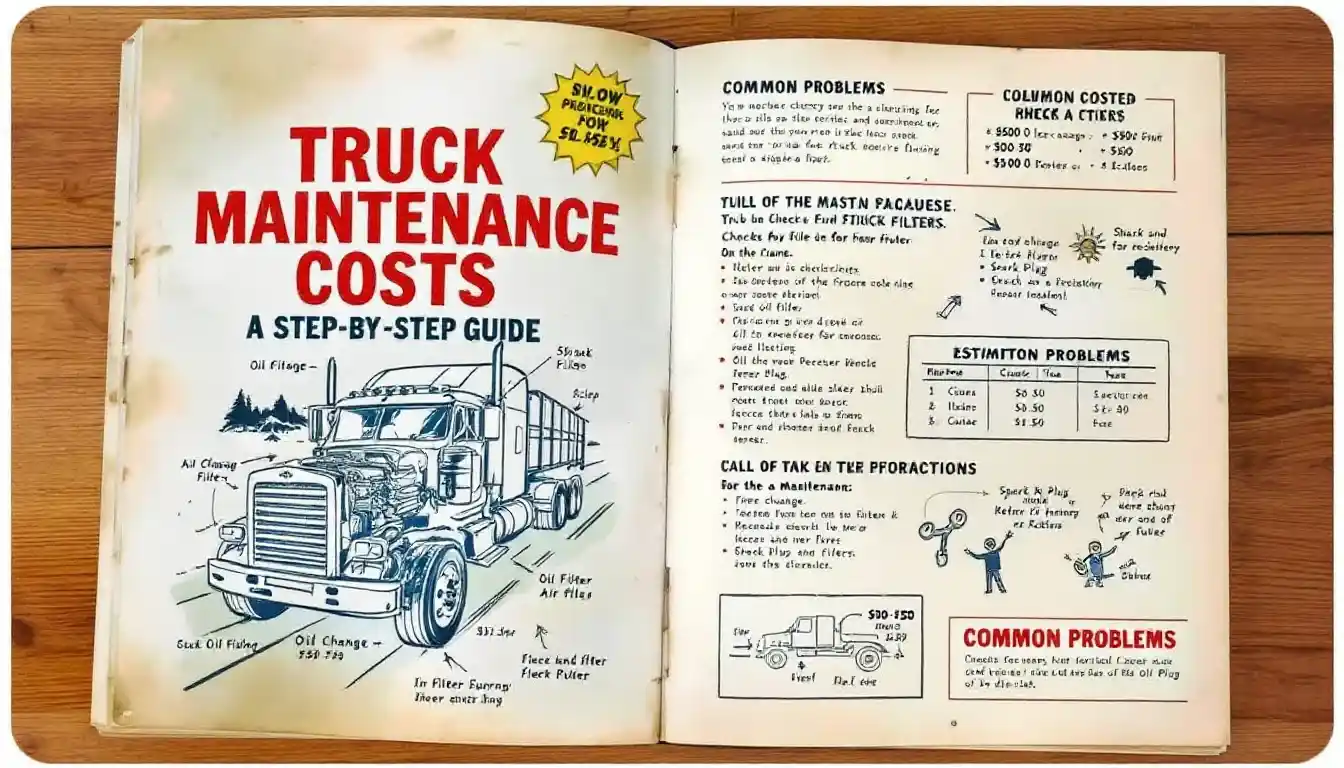

Cost of Truck Maintenance

A preventive maintenance routine saves money, ensures safer operations, and reduces breakdowns. A structured maintenance plan is key in maintaining a semi-truck to avoid costly repairs. Effective preventative maintenance can help save time and money.

Well-maintained trucks can achieve better fuel efficiency, leading to reduced operational costs and ensuring your own truck remains in good working order.

Average Costs

The average annual maintenance cost for a semi-truck is around $15,000. Typical annual maintenance costs for a semi-truck include regular inspections, part replacements, and necessary repairs.

In 2021, the maintenance costs for semi-trucks increased by 3-5%.

Cost-Saving Tips

Planning your maintenance budget per mile helps manage truck maintenance costs effectively. Proactive maintenance prolongs truck life and minimizes major repair expenses. Addressing fluid leaks promptly can prevent larger mechanical issues and costly repairs in the future.

Implementing mobile apps for maintenance reporting streamlines communication between drivers and fleet management, improving response times. Mobile reporting tools empower drivers to document observations and maintenance needs instantly, enhancing overall fleet efficiency.

Regularly checking tire pressure can enhance fuel efficiency and improve vehicle handling.

Common Maintenance Issues and Solutions

Driver-conducted inspections can uncover defects that might cause accidents if not addressed. Systematic pre-trip checks help identify potential mechanical issues, preventing major breakdowns during trips, highlighting the focus difference in safety between thorough inspections and neglect.

Addressing these common preventative maintenance tips issues proactively can significantly enhance the safety and reliability of your fleet.

Electrical System Problems

Battery malfunction is the most common cause of truck breakdowns. Avoid battery malfunction by keeping batteries clean and charged, and ensuring electrical connections are clean. The electrical system should be included in preventative maintenance due to the stress from long-distance driving and frequent stops.

It is best to check the electrical system before winter to prepare for colder climates.

Fluid Leaks

Oil leaks, if not addressed, can lead to serious engine issues due to loss of lubrication. Puddles under the truck after parking can indicate leaks in fluids like coolant or oil.

Detecting and repairing fluid leaks is crucial for maintaining the truck’s performance and preventing major issues.

Tire Wear

Tire wear can significantly impact vehicle safety and operational efficiency in a trucking fleet. Improper tire pressure, misalignment, and overloading can cause uneven tire wear. Regular inspections can help identify signs of tire condition issues like dry rot or uneven wear, which should be addressed immediately.

Implementing proactive tire management strategies can extend tire lifespan and enhance overall safety for the fleet, including the use of steer tires.

Empowering Drivers for Maintenance

A consistent daily inspection routine identifies potential issues before they lead to accidents. Regular inspections help in identifying potential issues before they escalate, leading to improved safety and reliability.

Implementing driver scorecards can help assess and improve driving habits, which can lead to lower maintenance costs. Encouraging driver involvement in maintenance reporting supports enhanced fleet reliability and proactive management of vehicle conditions.

Pre-Trip Inspections

Driver pre-trip inspections enhance safety and identify maintenance issues early. Inspecting exterior lighting before driving is essential to identify burnt-out bulbs and ensure all lights are functioning. Dim or flickering lights may suggest a failing alternator or loose battery connections, warranting immediate inspection. Flickering headlights can indicate potential electrical issues in a truck.

Drivers should conduct brake checks regularly, especially every time they stop their vehicle. Frequent maintenance checks can help identify and resolve issues early, preventing more serious problems down the line. It takes less time to complete pre-trip inspections than to refuel, making them a quick yet vital task.

It is important for drivers to inspect their trucks regularly to address minor issues before they escalate into major matter problems.

Reporting Procedures

Empowering drivers to be involved in maintenance reporting leads to better fleet reliability and quicker identification of issues. Implementing easy-to-use mobile apps for drivers allows for immediate access to report maintenance needs and observations.

Driver-performed pre-trip inspections are crucial for early detection of potential maintenance issues and can be easily reported through mobile apps. Using mobile apps for maintenance reporting not only streamlines the communication but also enhances accountability among drivers regarding the truck’s condition.

Tools and Equipment for Effective Maintenance

Having the right tools and equipment is crucial for performing effective maintenance on trucks, ensuring their reliability and longevity. Basic hand tools are crucial for everyday maintenance tasks, ensuring quick fixes and routine checks. Advanced diagnostic systems help technicians accurately diagnose and fix complex issues in modern truck models.

Using appropriate tools, from basic hand tools to advanced diagnostics, is vital for maintaining fleet efficiency and performance.

Basic Hand Tools

A set of basic hand tools includes wrenches, screwdrivers, pliers, and sockets for a variety of everyday maintenance tasks. Having an adjustable wrench is crucial for tightening and loosening different sizes of nuts and bolts. Additionally, a torque wrench is important for ensuring that bolts are tightened to the manufacturer’s specifications without over-tightening.

A multimeter is a specialty tool for diagnosing electrical issues in trucks.

Diagnostic Systems

Advanced diagnostic tools are essential for identifying and resolving complex issues in modern truck models. These tools provide detailed insights into the truck’s systems, allowing for precise troubleshooting of malfunctions. Examples of advanced diagnostic tools include onboard diagnostics (OBD) systems and specialized software that connects to the truck’s electronic control units.

Maintaining and utilizing these diagnostic systems effectively can lead to improved safety, efficiency, and reduced unplanned downtimes in fleet operations, ensuring everything is working properly.

Importance of Adhering to Regulations

Maintenance regulation compliance is crucial to avoid legal repercussions for trucking companies. Adhering to both federal and state regulations ensures that trucks are maintained to the highest safety standards, reducing the risk of accidents and enhancing overall fleet reliability.

Federal Requirements

The FMCSA requires that semi-trucks adhere to specific safety and functional requirements to ensure safety on the road. These specific requirements include adhering to maintenance schedules, ensuring all safety equipment is functional, and passing inspection criteria. According to FMCSA regulations, maintaining accurate maintenance records is crucial to demonstrate adherence to regulations and to ensure trucks are roadworthy.

Adhering to FMCSA requirements and maintaining thorough records are essential for ensuring the safety of the fleet and compliance with federal regulations.

State-Specific Rules

State-specific maintenance rules are essential for ensuring that truck operations comply with local laws and regulations in each location. Example of different types of state-specific rules can include requirements for inspections, emissions standards, and maintenance recordkeeping.

Federal requirements serve as a baseline for maintenance practices, but states may impose additional or stricter regulations. Adherence to state-specific and federal rules ensures smooth fleet operations, enhancing safety and reducing legal risks.

Planning for Long-Term Reliability

Replacing older vehicle parts with modern, more efficient components can lower long-term repair costs. Long-term maintenance strategies are essential to ensure fleet reliability and minimize costly repairs. Proactive maintenance planning helps reduce long-term costs associated with unexpected repairs.

Implementing a long-term maintenance plan encourages routine checks, enhancing vehicle performance and safety in the long run.

Scheduled Major Services

A detailed preventive maintenance schedule is essential for maintaining truck performance based on mileage and manufacturer’s recommendations. Regular service intervals should be established for engine oil changes, air filter replacements, and transmission checks to prolong engine life. Scheduled brake system maintenance and inspections are critical for optimal performance and safety.

Adjusting maintenance routines for seasonal changes is necessary as different weather conditions can impact truck systems, such as cooling and battery performance.

Tracking Maintenance History

Documentation of maintenance activities is essential for proving compliance with FMCSA regulations. An organized record of maintenance activities allows for better forecasting of future service needs and cost management.

A detailed log of services performed allows for better forecasting of future maintenance needs and budgeting. This can help in managing operational costs effectively and ensuring that the fleet remains in top condition.

Summary

In conclusion, maintaining a well-structured truck maintenance plan is essential for the reliability, safety, and efficiency of your fleet. Regular inspections, preventive maintenance, and adherence to regulations play a crucial role in reducing maintenance costs and avoiding unexpected breakdowns. By empowering drivers, using the right tools, and planning for long-term reliability, you can ensure that your trucks remain in optimal condition. Implement these tips to keep your fleet running smoothly and your business thriving.