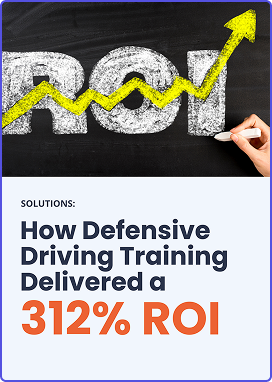

Mike Roeth is the Executive Director of the North American Council for Freight Efficiency (NACFE), a nonprofit organization that promotes the adoption of technologies and practices to enhance freight efficiency and sustainability across North America. With nearly 40 years in the commercial vehicle industry, he specializes in bringing green truck technologies into real-world applications at scale. Mike also serves as the trucking lead at RMI and has held leadership roles at Navistar and Behr/Cummins. Recognized as an industry influencer by FleetOwner and honored as the 2020 SAE L. Ray Buckendale Lecturer, he is a prominent voice in advancing freight efficiency and decarbonization.

Here’s a glimpse of what you’ll learn:

- [4:00] How Mike’s journey from an Ohio hog farm instilled the pragmatic, no-BS approach that drives his work today

- [7:00] The 86 different technologies fleets can deploy to save fuel – from major aerodynamic improvements to simple mud flap changes

- [11:00] Why safer driving naturally leads to better fuel efficiency and creates a “win-win-win” scenario

- [14:00] The cultural challenge of speed versus efficiency and how “faster doesn’t always mean more profitable”

- [18:00] How parking shortages and hours of service regulations compound driver stress and fuel consumption

- [22:00] Why the “messy middle” of fleet decarbonization is both challenging and full of opportunity

- [26:00] The surprising simplicity of electric trucks and why drivers universally love them

- [30:00] Key metrics for measuring success across diesel, electric, natural gas, and hydrogen vehicles

- [34:00] Practical advice for fleets to start their electrification journey without overwhelming investment

- [38:00] How driver training today prepares fleets for tomorrow’s alternative fuel technologies

In this episode…

Fuel prices are rising, driver stress is mounting, and environmental pressures are reshaping the freight landscape. Amidst all this, how can fleets find a balance between cutting costs and keeping drivers safe and effective behind the wheel? With the trucking industry facing what experts call the “messy middle” of decarbonization—caught between traditional diesel operations and emerging alternative fuel technologies—fleet managers need strategies that work today while preparing for tomorrow.

According to Mike Roeth, a long-time industry leader and efficiency advocate, the key lies in smarter, safer driving habits that naturally improve fuel economy. He highlights how even small behavior changes — like reducing speed or using predictive cruise control — can create a ripple effect across fuel savings, maintenance costs, and driver well-being. These incremental adjustments not only support bottom-line performance but also help fleets prepare for new technologies like electric trucks. By aligning safety with operational efficiency, fleets can reduce burnout and navigate the messy middle of decarbonization with greater confidence.

In this episode of Roadrageous, hosts Liam Hoch and Chad Lindholm sit down with Mike Roeth, Executive Director of the North American Council for Freight Efficiency (NACFE), to discuss how safer driving leads to lower fuel costs and longer-lasting trucks. They explore the cultural mindsets around speed, the role of driver training in energy efficiency, and how fleet habits are evolving with electrification. Mike also shares how simple actions today can prepare fleets for tomorrow’s technologies.

Quotable Moments:

- “For every one mile an hour of speed, results in 0.1 mile per gallon in fuel costs. Between 70 and 60, that’s worth a whole mile per gallon – tens of thousands of dollars in fuel a year per truck.”

- “Safer driving is more fuel efficient, and being more fuel efficient in your driving makes the vehicle and your experience driving it safer.”

- “Simple usually wins in the end. If something’s simpler to do, people do it. If it’s harder, people won’t do it.”

- “These drivers love these electric trucks, as long as they’ve got the range to get ’em home and they can have confidence in them.”

- “When you come to a fork in the road, take it. I don’t think this is a time to completely sit on the sideline and spectate.”

Action Steps:

- Focus on speed management: Implement policies and training that encourage optimal speeds rather than maximum speeds for immediate fuel savings.

- Deploy predictive cruise control: Utilize advanced cruise control systems that use topography data to optimize fuel consumption.

- Start with energy efficiency: Begin with proven fuel-saving technologies before moving to alternative fuels – the habits transfer across all powertrains.

- Take incremental steps toward electrification: Purchase electric pickup trucks, yard tractors, or delivery vehicles to build organizational knowledge.

- Measure what matters: Establish metrics that work across diesel, electric, and alternative fuel vehicles to track progress consistently.

- Address driver stress holistically: Recognize that parking challenges and time pressures drive speed decisions that hurt efficiency.

Navigating Fleet Efficiency in the Age of Decarbonization

In a recent episode of Roadrageous, hosts Liam Hoch and Chad Lindholm welcomed Mike Roeth, Executive Director of the North American Council for Freight Efficiency (NACFE), to discuss the intersection of safety, efficiency, and the evolving landscape of fleet decarbonization.

From Farm Wisdom to Fleet Innovation

Mike’s journey began on an Ohio hog farm, where his father’s practical approach to commodity pricing and agricultural economics laid the foundation for his data-driven, no-nonsense approach to fleet efficiency. This pragmatic background, combined with engineering education and decades in heavy-duty vehicle development, positioned him uniquely to help fleets navigate the complex world of fuel efficiency and alternative technologies.

Key Discussion Points:

The Comprehensive Approach to Efficiency: Mike detailed NACFE’s work tracking 86 different technologies that fleets can implement to save fuel – ranging from major investments like automated manual transmissions and aerodynamic devices to simple changes like switching from solid mud flaps to “fly swatter” versions. This comprehensive approach recognizes that efficiency comes from multiple small improvements rather than single silver bullets.

The Safety-Efficiency Connection: A central theme of the conversation was the natural alignment between safer driving and fuel efficiency. Mike explained how reducing speed, avoiding harsh acceleration and braking, and using advanced cruise control systems create a “win-win-win” scenario – improving safety, reducing fuel costs, and extending vehicle maintenance intervals.

Cultural Challenges Around Speed: The discussion explored the deeply ingrained trucking culture that equates speed with profitability – “if the wheels aren’t turning, we’re not earning.” Mike challenged this assumption, demonstrating how the stress of constant passing, the fuel penalty of higher speeds, and the compounding effects of traffic situations often make slower driving more profitable overall.

The Stress Factor: An often-overlooked aspect of efficiency is driver stress. Mike shared insights about how parking shortages force drivers to speed up to secure overnight spots earlier, creating a cycle that reduces both safety and efficiency. His personal experience driving at 63 mph versus 68 mph in his RV demonstrated how lower speeds reduce stress and extend driving capability.

The “Messy Middle” of Decarbonization

Mike introduced the concept of the “messy middle” – the transitional period where fleets must navigate between traditional diesel operations and emerging alternative fuel technologies. This phase presents both challenges and opportunities as various solutions compete for market share.

Electric Vehicle Reality Check: Despite his background in diesel engines, Mike has become a strong advocate for electric trucks, comparing them to “ginormous golf carts” that offer smooth operation, quiet cabs, and simplified maintenance. He emphasized that driver acceptance is universal once they experience the comfort and ease of operation.

Technology Simplification: A key insight was Mike’s observation that “simple usually wins in the end.” Electric vehicles, with their reduced complexity compared to modern diesel engines with emissions systems, represent a return to simpler operation that naturally appeals to both drivers and technicians.

Metrics Evolution: The conversation explored how fleet metrics must evolve to accommodate multiple fuel types. Mike’s upcoming “Run on Less” campaign will track 13 vehicles across four fuel types, demonstrating how efficiency measures translate across diesel, natural gas, battery electric, and hydrogen fuel cell technologies.

Practical Implementation Strategies

Mike provided concrete advice for fleets looking to begin their efficiency and electrification journey:

Start Where You Are: Rather than waiting for perfect solutions, fleets should begin with proven efficiency technologies and driver training that will benefit any powertrain they eventually adopt.

Incremental Electrification: He recommended starting with electric pickup trucks, yard tractors, or delivery vehicles to build organizational knowledge and comfort with the technology before moving to over-the-road applications.

Right-Sizing Solutions: The discussion emphasized matching technologies to specific use cases – natural gas for return-to-base operations, electric for predictable routes, and continued diesel optimization where alternatives aren’t yet viable.

Industry Collaboration and Future Vision

Throughout the conversation, Mike highlighted the trucking industry’s collaborative spirit in solving complex challenges. He emphasized that the transition to alternative fuels requires the same problem-solving approach that has driven decades of efficiency improvements.

Building on Success: Mike noted how NACFE’s work helping the industry improve from 5.5 to 6.6+ miles per gallon provides a foundation for further improvements, whether through continued diesel optimization or alternative fuel adoption.

Educational Imperative: The discussion underscored the critical role of industry organizations, training companies, and media in helping fleets navigate increasingly complex technology choices without becoming overwhelmed.

Conclusion

Mike Roeth’s approach to fleet efficiency demonstrates that success in the “messy middle” of decarbonization comes from building on proven fundamentals while remaining open to technological evolution. By focusing on driver behavior, incremental improvements, and strategic technology adoption, fleets can achieve immediate benefits while positioning themselves for long-term success with alternative fuels.

The key insight: efficiency isn’t about choosing between diesel and electric – it’s about optimizing whatever powertrain you’re using while preparing for the future. The driving habits, training programs, and operational practices that save fuel in diesel trucks will prove equally valuable in electric vehicles, creating a bridge between today’s operations and tomorrow’s sustainable transportation future.

Resources mentioned in this episode:

- Mike Roeth on LinkedIn

- North American Council for Freight Efficiency (NACFE)

- Run on Less Campaign

- Freight Efficiency with NACFE’s Mike Roeth and Friends Podcast

- Liam Hoch on LinkedIn

- Chad Lindholm on LinkedIn

- IMPROVLearning

- RMI (Rocky Mountain Institute)

Sponsor for this episode: This episode is brought to you by IMPROVLearning.

At IMPROVLearning, we’re dedicated to transforming driver education through innovative, research-backed training methods. Our SPIDER™ Driver Training platform combines humor with proven brain-training techniques to help drivers anticipate and avoid potential dangers on the road. With over four million students trained, we know that learning sticks best when it’s engaging, short, and actively tested — resulting in fewer crashes, violations, and safer drivers overall.

To learn more about how IMPROVLearning makes roads safer one driver at a time, visit improvlearning.com.